Vacuum Pump and Vacuum Packaging Suppliers

The Leading Vacuum Packing Machine Supplier

delivering under pressure for all industries and applications

We are a vacuum packaging machine supplier offering purpose-built solutions for the food and manufacturing industry.

We offer purpose-built vacuum packaging solutions for every product, every demand, every market and every application. We deliver by using advanced technology, quality construction and superior design, backed up all the way with support of every kind, from servicing to parts and operational advice.

We strive to support growth, sustainability and safety for our customers through our efficient service, strong work ethic and customer-oriented policy that makes VACPAC a reliable, loyal and committed business partner.

OUR PROCESS

Vacuum Packaging

With over 20 years of experience under our belt as a vacuum packing machine supplier, VACPAC offers a comprehensive suite of vacuum packaging services that cater to diverse industries. Our dedicated team of professionals is committed to understanding your unique requirements and tailoring our solutions to meet your exact specifications.

SOLUTIONS

DESIGN

VACPAC is able to custom design and draft your next vacuum or packaging project to complement workflow specific to your business. No job is too big or small, and we will work with you to create a tailor-made design, handling all elements from electrical to mechanical while ensuring an efficient and high-performing system.

EQUIPMENT

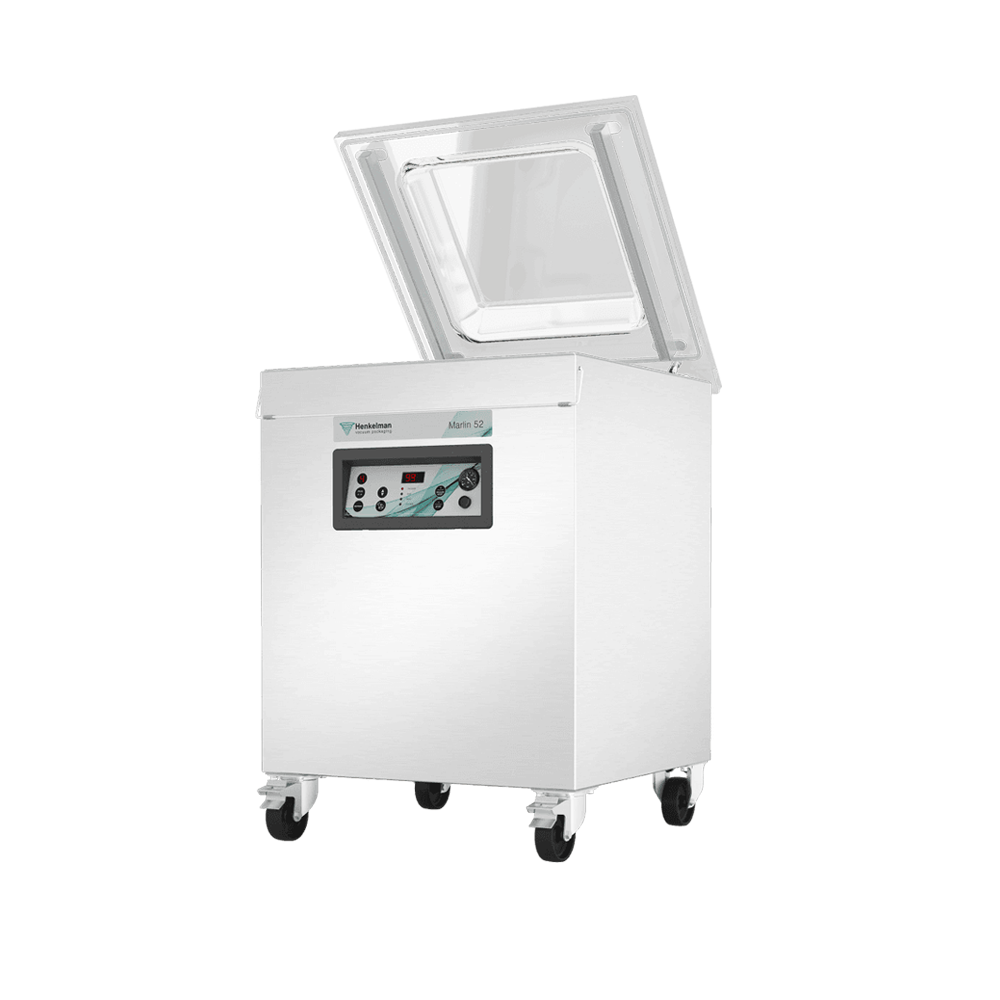

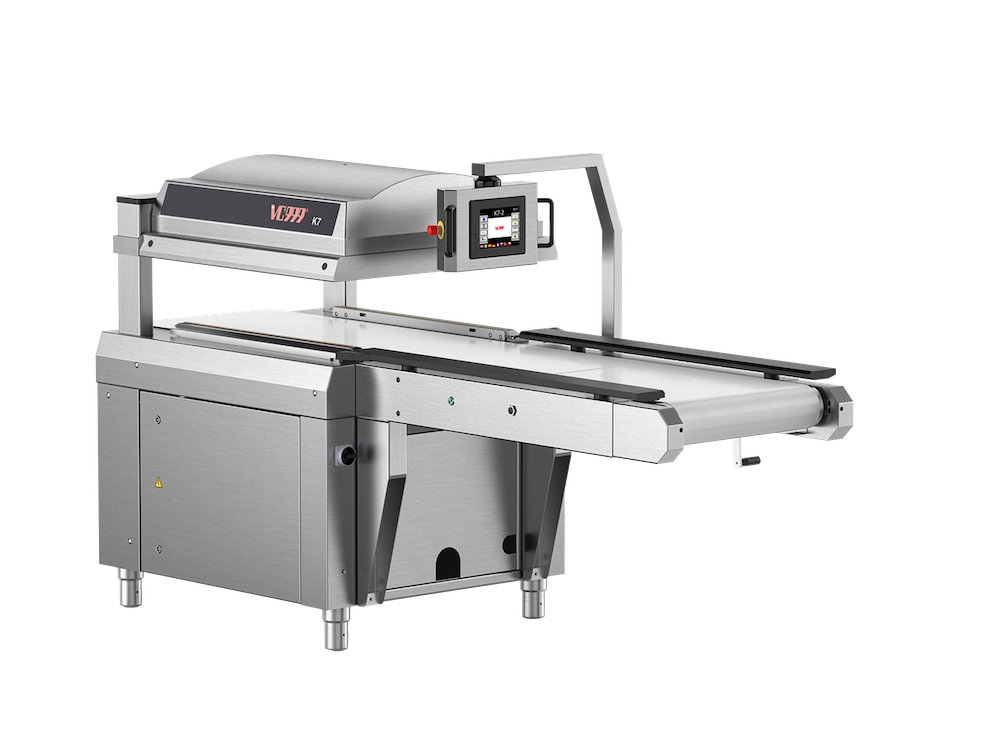

As a world-class vacuum packing machine supplier, we use only the world’s best brands. VACPAC has an extensive range of equipment available to suit any number of needs, including chamber machines, belt machines, thermoformers, tray sealers, shrink tunnels, chill tanks, drying tunnels, and conveyor systems.

FABRICATION

We employ a team of qualified electricians and mechanical fitters with the experience and skills to fabricate whatever is required. The fabricating team can design and build small to medium-sized mechanical and electrical projects in-house, and they’ll work closely with you throughout the entire process.

INSTALLATION

As a vacuum packing machine supplier, we can install most food processing and packaging equipment, plus accessories, whether we supply them or not. Everything from simple vacuum pump replacements to mobile packaging machinery, as well as fully automated packaging lines with remote vacuum pump systems. For large, time-sensitive projects, we partner with industry professionals to ensure a smooth and accurate job is delivered on time every time.

INTEGRATION

No matter the complexity of the project, VACPAC can integrate your newly installed equipment so you can get back to business sooner. After installation, you can rely on our team to completely integrate your equipment into existing electrical and mechanical control systems. Whether it’s a simple emergency ring circuit or a complex SCADA system, we’ll have it up and running in no time.

WHAT WE OFFER

Vacuum Packaging Servicing

VACPAC’s range of maintenance and service packages covers the three most required areas: preventative maintenance, responsive services, and emergency breakdowns.

PREVENTIVE MAINTENANCE AGREEMENT (PMA)

Conducted on a regular, scheduled, ongoing basis to ensure maximum operating time and optimal output, prevent faults in advance and reduce unplanned downtime. Each PMA is client and asset-specific and supported by discount rates and guarantees.

RESPONSIVE SERVICES

Conducted on a regular, scheduled, ongoing basis to ensure maximum operating time and optimal output, prevent faults in advance and reduce unplanned downtime. Each PMA is client and asset-specific and supported by discount rates and guarantees.

EMERGENCY BREAKDOWNS

We provide fast and responsive service times and access to essential parts and components to ensure service can resume as promptly as possible.

TRAINING

When you purchase a machine through VACPAC, we’ll train your staff to maintain its productivity, and understand how to navigate potential faults safely and effectively so your machine runs at full operating capacity.

REBUILDS AND OVERHAULS

Undertaking a rebuild with VACPAC can extend the lifespan of your machine or equipment and ensure it’s up to date with the most modern components available for your specific industry or application.Conducting an overhaul through VACPAC means a thorough ‘health check’ of your machine and preventative maintenance attention to any components requiring service or replacement.

LOAN EQUIPMENT

VACPAC has machines and equipment available for loan so clients can continue to operate while their equipment is being repaired or rebuilt in our workshop, or waiting for a specific part. It’s another way we do whatever we can to help.

PREVENTIVE MAINTENANCE AGREEMENT (PMA)

Conducted on a regular, scheduled, ongoing basis to ensure maximum operating time and optimal output, prevent faults in advance and reduce unplanned downtime. Each PMA is client and asset-specific and supported by discount rates and guarantees.

RESPONSIVE SERVICES

We provide fast and responsive service times and access to essential parts and components to ensure service can resume as promptly as possible.

EMERGENCY BREAKDOWNS

Quick, onsite help whenever an emergency arises. We analyse the fault, rectify the situation and suggest immediate implementations for improvement.

TRAINING

When you purchase a VACPAC machine, we’ll train your staff to maintain its productivity and navigate its potential faults safely so your machine can run at full operating capacity.

REBUILDS AND OVERHAULS

A VACPAC rebuild extends the lifespan of your machine and ensures it’s up to date with the most modern components for your industry. A VACPAC overhaul is a thorough “health check” of your machine that tends to any components requiring servicing or replacement.

LOAN EQUIPMENT

VACPAC has machines and equipment available for hire so clients can continue to operate while we repair or rebuild their machines in our workshop or while they wait for specific parts to be ready.

WHAT WE OFFER

Vacuum Packaging Servicing

VACPAC’s range of maintenance and service packages covers the three most required areas: preventative maintenance, responsive services, and emergency breakdowns.

PREVENTIVE MAINTENANCE AGREEMENT (PMA)

Conducted on a regular, scheduled, ongoing basis to ensure maximum operating time and optimal output, prevent faults in advance and reduce unplanned downtime. Each PMA is client and asset-specific and supported by discount rates and guarantees.

RESPONSIVE SERVICES

We provide fast and responsive service times and access to essential parts and components to ensure service can resume as promptly as possible.

EMERGENCY BREAKDOWNS

Quick, onsite help whenever an emergency arises. We analyse the fault, rectify the situation and suggest immediate implementations for improvement.

TRAINING

When you purchase a VACPAC machine, we’ll train your staff to maintain its productivity and navigate its potential faults safely so your machine can run at full operating capacity.

REBUILDS AND OVERHAULS

A VACPAC rebuild extends the lifespan of your machine and ensures it’s up to date with the most modern components for your industry. A VACPAC overhaul is a thorough “health check” of your machine that tends to any components requiring servicing or replacement.

LOAN EQUIPMENT

VACPAC has machines and equipment available for hire so clients can continue to operate while we repair or rebuild their machines in our workshop or while they wait for specific parts to be ready.

Premium Vacuum Packaging Equipment

VACPAC uses, loans, and sells only the best equipment in the business. We have top-quality European brands with reliable track records and longstanding reputations for engineering excellence.

Rental: Vacuum Packaging Suppliers

Renting a high-quality European vacuum packaging machine is an affordable, low-commitment alternative to buying or owning. As a vacuum packaging supplier, VACPAC offers both short and long-term vacuum packaging machine rental options for benchtops, free-standing, swing-lid and automatic machines. The advantages of renting from a vacuum packing machine manufacturer include:

- No capital outlay of funds.

- Rental payments are fully tax-deductible.

- Machines are quality European models routinely serviced and maintained.

- All machines are delivered and commissioned with staff training provided.

- You can upgrade or downgrade a machine on request to meet your business needs.

- 24/7 support with immediate response to machine failures or repairs when applicable.

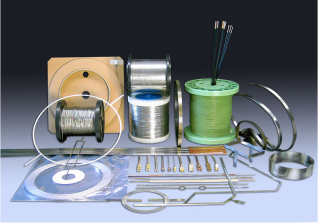

Vacuum Packaging Spare Parts

We are a vacuum packaging machine manufacturer who ensures our technology is backed by superior support and maintenance. VACPAC stocks, orders, and dispatches high-quality replacement and OEM vacuum packaging machine parts, equipment, and tools to keep your machines running optimally.

Vacuum Pumps

Whatever the situation or application requiring a vacuum pump, VACPAC can provide the products, services, and solutions you need.

Upgrades

We can upgrade your existing pump to one that is more closely aligned with your current needs and budget.

SERVICING

Our vacuum pump maintenance helps deliver more reliable performance and a longer lifespan.

Optimisation

As your business changes, so do the demands on your equipment. We can help you maximise what you have and adapt to your company’s growth.

Sales

Our friendly, helpful vacuum packing machine suppliers always recommend the most suitable option for your needs, budget, and business.

Vacuum Pumps

Whatever the situation or application requiring a vacuum pump, VACPAC can provide the products, services, and solutions you need.

Upgrades

We can upgrade your existing pump to one that is more closely aligned with your current needs and budget.

Optimisation

As your business changes, so do the demands on your equipment. We can help you maximise what you have and adapt to your company’s growth.

Servicing

Our vacuum pump maintenance helps deliver more reliable performance and a longer lifespan.

Sales

Our friendly, helpful vacuum packing machine suppliers always recommend the most suitable option for your needs, budget, and business.

Visit Our Showroom

VACPAC makes life easier with a showroom every client can take advantage of to gain a greater understanding of what we, as vacuum packaging suppliers, have to offer. The VACPAC range includes everything from new industrial vacuum sealing machines to quality refurbished vacuum pumps.

TRUSTED BY